Customizable High-Capacity 115 Gallon Industrial Safety Locker with Explosion-proof Air Vents for Military Installations and Distribution Centers

1. The Fortress of Industrial Safety

When it comes to the storage of hazardous materials in high-security environments like military installations, aerospace hangars, and global distribution centers, there is zero room for error. Small safety cabinets are insufficient for the sheer volume of chemicals required to keep these operations running. You need a powerhouse.

The 115 Gallon Industrial Safety Locker is our largest and most robust model, designed to be the definitive “fortress” for your flammables. This high-capacity unit is engineered to consolidate large inventories of hazardous liquids into one centralized, ultra-secure, and fully compliant location.

2. Why High-Capacity (115 Gallon) Industrial Safety Locker is the Strategic Choice

In massive facilities, decentralized storage leads to “inventory chaos,” making it difficult for safety officers to track chemical expiration dates or ensure all small cabinets are properly locked.

- Centralized Control: By moving to a 115-gallon locker, you can store up to 24 to 30 five-gallon pails in a single unit.

- Reduced Footprint: Instead of having five small cabinets scattered across a warehouse, one 115-gallon locker provides a cleaner, more organized layout, freeing up valuable floor space.

- Cost Efficiency: Buying and maintaining one large locker is significantly more cost-effective over a 10-year period than managing multiple smaller units.

3. Advanced Engineering: Built for Military & Industrial Rigor

Military installations and heavy-duty distribution hubs operate 24/7. The furniture in these environments must withstand mechanical impacts, heavy vibrations, and constant door cycling.

A. Explosion-Proof Air Vents with Flame Arresters

The primary danger in large-scale chemical storage is the buildup of volatile vapors.

- Strategic Placement: Dual vents are located on both sides of the locker to encourage natural cross-ventilation.

- Flame Arresters: Each vent is equipped with a stainless steel flame arrester that acts as a thermal barrier, preventing an external fire from entering the locker and triggering a catastrophic explosion.

- Extraction Ready: These vents are threaded to allow for direct connection to industrial exhaust systems, a common requirement in petrochemical and military labs.

B. Double-Wall Fire-Tight Construction of Industrial Safety Locker

The locker features a double-layer 1.2mm (18-gauge) high-strength cold-rolled steel structure.

- The Insulating Barrier: A 38mm (1.5-inch) air gap between the walls serves as a thermal buffer, maintaining a lower internal temperature even when the exterior is exposed to extreme heat.

- Seamless Welding: Unlike bolt-together lockers, our “All-Welded” construction provides superior structural integrity and ensures that the cabinet remains liquid-tight.

4. Technical Specifications & Performance Data of Industrial Safety Locker

To assist facility managers in their procurement process, the following table outlines the rigorous technical standards of the 115 Gallon model.

| Feature | Technical Specification | Benefit / Compliance |

| Capacity | 115 Gallons / 435 Liters | High-volume consolidation |

| Material Grade | 18-Gauge Cold Rolled Steel | Industrial impact resistance |

| Locking System | Triple-Point Linkage + Padlock Hasp | Anti-theft & Dual-person control |

| Sump Depth | 50mm (2-inch) Leak-proof Tank | OSHA Secondary Containment |

| Coating | Lead-free Epoxy Powder Coating | Corrosion & Chemical resistance |

| Shelf Load | 150kg+ (Uniformly Distributed) | Supports heavy drums and pails |

| Certification | OSHA 1910.106 / NFPA Code 30 | Passes international safety audits |

5. Customization: Tailoring to Specific Mission Requirements

No two military or industrial sites are exactly the same. We offer extensive OEM/ODM customization to ensure the locker fits your operational “Mission Profile.”

- Reinforced Flooring: For facilities storing extremely heavy 55-gallon drums (if used as a spill bin), we can reinforce the bottom sump with extra-thick steel.

- Specialized Labeling: We provide customized safety signage in multiple languages or specific military-grade tactical markings.

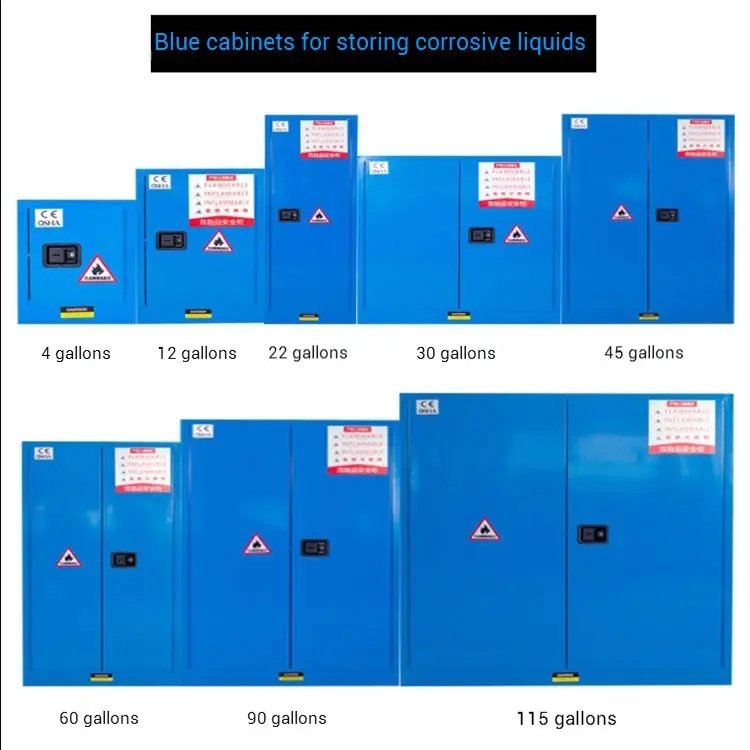

- Custom Colors: Beyond the standard safety yellow, we can produce lockers in “Olive Drab” for field use, “Navy Blue” for corrosive storage, or “Signal Red” for high-visibility combustible areas.

- Shelf Configuration: You can request additional galvanized shelves or specialized “Sliding Drawers” for easier access to deep-seated chemical bottles.

6. The 50mm Leak-Proof Sump: Environmental Insurance

In distribution centers, a single leaking chemical drum can result in a massive environmental fine.

- Secondary Containment: Our 115-gallon industrial safety locker features a deep 50mm secondary containment sump.

- Spill Mitigation: If a container fails, the liquid is trapped inside the locker’s base. This prevents the spill from reaching floor drains or contaminating warehouse inventory.

- Easy Maintenance: The smooth, epoxy-coated floor allows for quick neutralization and cleanup of the leaked substance.

7. Operational Use Cases

Military Installations

Military sites often store high-octane fuels, specialized lubricants for aircraft, and hazardous cleaning agents. The High-Capacity Industrial Safety Locker provides the security needed to prevent unauthorized access while ensuring that these materials are ready for deployment in a fire-safe environment.

Global Distribution Centers

Large warehouses managed by companies like Amazon or FedEx often have a “Hazardous Materials” zone. These industrial safety lockers are the industry standard for securing “Aerosol Cage” items or bulk solvents before they are shipped.

8. Safety & Compliance Checklist for Buyers

When selecting a 115-gallon industrial safety locker, ensure it meets the following criteria (all of which are standard in our model):

- [x] Does it have a ground connection? (Essential for static control during fuel transfer).

- [x] Is it finished with a lead-free coating? (Important for health and safety compliance).

- [x] Does it have a self-closing option? (Mandatory in many EU and US jurisdictions).

- [x] Are the shelves adjustable? (Crucial for storing various drum heights).

9. Frequently Asked Questions (FAQ)

Q1: How is a 115-gallon industrial safety locker shipped?

A: Due to its size and weight, it is shipped in a reinforced “Heavy-Duty Export Crate” with a pallet base to allow for easy forklift movement upon arrival at your distribution center.

Q2: Can this industrial safety locker be used for “Explosives”?

A: This industrial safety locker is designed for Flammable and Combustible Liquids. For Class 1 Explosives, please contact us for our specialized “Magazine” series, which features different venting and wall thickness requirements.

Q3: Is it possible to add digital electronic locks?

A: Yes. For high-security military zones, we can customize the locker with digital keypad locks or biometric scanners to ensure a digital audit trail of who accessed the hazardous materials.9. SEO & Marketing Summary

10.

If you are looking for the best industrial safety locker for high-volume storage, our Customizable 115 Gallon Safety Cabinet is the answer. With its explosion-proof vents, high-load capacity, and military-grade durability, it is the trusted choice for distribution centers and government installations worldwide. Don’t settle for inferior storage—invest in a cabinet that provides a lifetime of protection.