What is the Difference Between HDPE and ABS Plastic Lockers for Outdoor Use?

When planning a large-scale storage project—whether for a high-traffic water park, a luxury beach resort, or a modern school campus—selecting the right material is a critical procurement decision. In the B2B sector, “plastic” is a broad term, but the performance gap between ABS (Acrylonitrile Butadiene Styrene) and HDPE (High-Density Polyethylene) can determine your facility’s maintenance costs for the next decade.Let us figure out the difference between HDPE and ABS plastic lockers.

As a leading China ABS locker manufacturer, we’ve seen how choosing the wrong polymer can lead to sagging shelves or warped doors. This comprehensive guide provides a technical and economic comparison to help facility managers maximize their ROI

Difference Between HDPE and ABS Plastic Lockers

1. Material Science 101: ABS vs. HDPE

What is ABS Plastic?

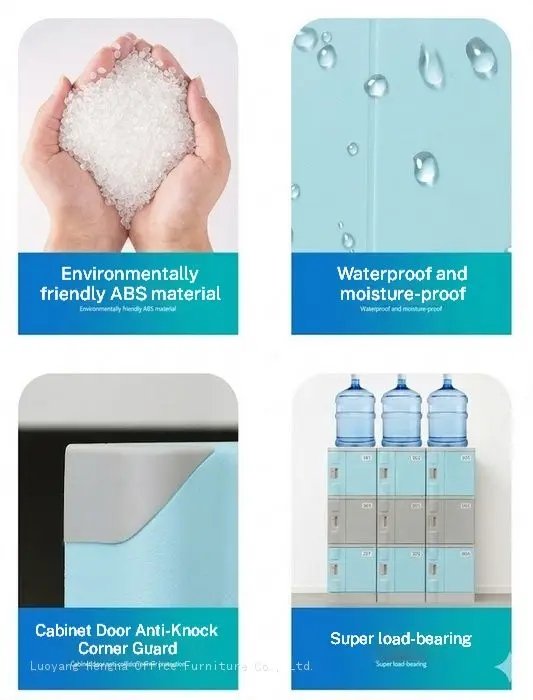

ABS is an engineering thermoplastic known for its exceptional rigidity and dimensional stability. It is a terpolymer composed of Acrylonitrile (for chemical resistance), Butadiene (for impact toughness), and Styrene (for a smooth, rigid finish). In the locker industry, ABS is synonymous with “premium strength.”

What is HDPE Plastic?

HDPE (High-Density Polyethylene) is a petroleum-based polymer with a high strength-to-density ratio. It is naturally more flexible and “waxy” than ABS. While HDPE is incredibly durable, it lacks the structural stiffness required for tall, modular locker banks without additional reinforcement.

2. Technical Performance Comparison Table

For B2B buyers, data speaks louder than marketing slogans. Here is how the two materials compare across key metrics:

| Key Feature | ABS Modular Lockers (HENGNA Style) | Solid HDPE Lockers |

| Structural Rigidity | Excellent (Maintains shape under load) | Moderate (Can flex or sag) |

| Impact Resistance | High (Energy absorbing) | Very High (Pliable) |

| Surface Finish | Smooth, Glossy, Professional | Waxy, Matte, Textured |

| Heat Deflection | High (Stable in tropical sun) | Lower (Prone to thermal expansion) |

| Modular Assembly | Interlocking DIY Design | Usually Pre-assembled/Welded |

| Landed Cost | Lower (Flat-pack shipping) | Higher (Bulky shipping) |

3. Critical Factors for Outdoor & Semi-Outdoor Use

UV Resistance and Photodegradation

The primary threat to outdoor lockers is UV radiation.

- ABS Solution: Modern ABS lockers for outdoor use are enriched with UV-stabilizing additives. These additives prevent the polymer chains from breaking down, ensuring the locker doesn’t become brittle or fade.

- HDPE Reality: HDPE is naturally UV-stable but dark colors tend to absorb heat, leading to “thermal expansion”. In extreme summer heat, HDPE doors may expand and “stick,” whereas ABS maintains its precise tolerances.

Corrosion and Salt-Spray Resistance

In coastal areas (beaches, marinas) or chlorinated environments (swimming pools), traditional steel lockers rust within 24 months.

- The Winner: Both ABS and HDPE are 100% rustproof and corrosion-resistant. However, the smooth surface of ABS is easier to wipe clean of salt deposits and grime than the waxy surface of HDPE.

4. Maintenance, Hygiene, and Vandalism

Anti-Bacterial and Easy-Clean Surfaces

For hospitals and food processing plants, hygiene is non-negotiable.

- ABS Lockers feature a non-porous surface that inhibits mold growth and is resistant to harsh chemical sanitizers.

- HDPE is chemically inert but its softer surface can develop deep scratches where bacteria can hide.

Impact and Scratch Resistance

In high-energy environments like school corridors or sports clubs:

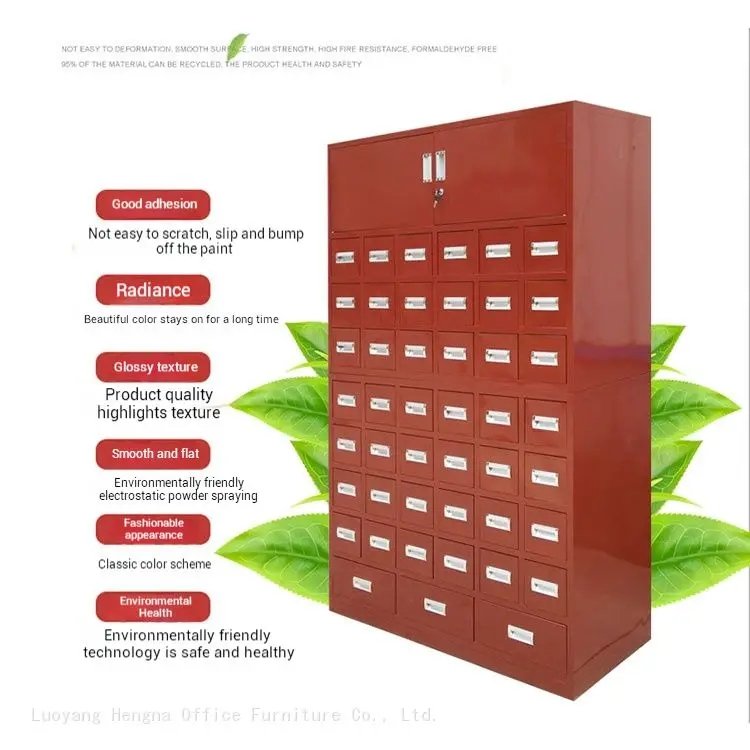

- ABS has high surface hardness, making it resistant to scratches from keys, coins, or equipment.

- HDPE is extremely hard to crack, but very easy to “carve” into. For public venues, ABS typically looks “newer” for a longer period.

5. The Economic Edge: Why B2B Buyers Prefer Modular ABS

Shipping Logistics (Landed Cost)

European and American importers focus heavily on the Landed Cost.

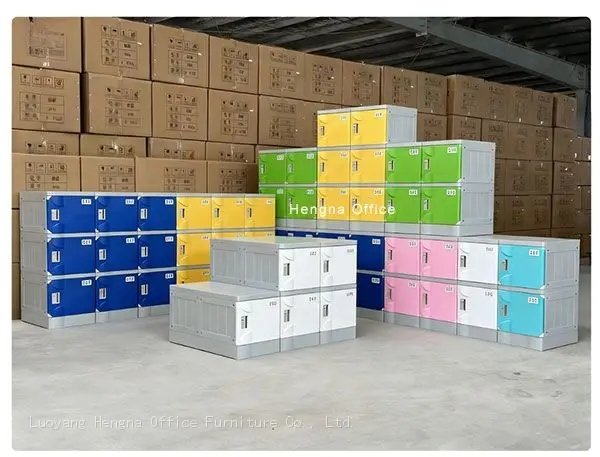

- Flat-Pack Efficiency: ABS lockers are designed for Knock-Down (KD) assembly. You can fit up to 300% more units in a 40HQ container compared to pre-assembled HDPE units. This drastically reduces the carbon footprint and shipping cost per unit.

Labor and Installation

With rising labor costs in the West, the Tool-Free Assembly of modular ABS lockers allows facility staff to install hundreds of units in a single weekend without hiring expensive contractors.

6. Sustainable Development & ESG Compliance

Modern procurement must align with Environmental, Social, and Governance (ESG) goals.

- 100% Recyclability: Both polymers are fully recyclable, fitting perfectly into the circular economy.

- Longevity: By choosing a material that lasts 15+ years without rusting, you reduce the environmental impact of frequent replacements.

7. Which One is Right for Your Project?

- Choose ABS Lockers if: You need professional aesthetics, modular flexibility, low shipping costs, and a rigid structure for schools, gyms, or offices.

- Choose HDPE Lockers if: You are in a heavy-industrial chemical plant where extreme solvent resistance is the only priority.

8. Final Verdict: Which Material Wins?

The Case for ABS (The All-Rounder)

ABS is the superior choice for 90% of B2B applications including Schools, Gyms, Hospitals, and Offices. It offers a better aesthetic, easier assembly, lower shipping costs, and high structural rigidity. It is the “modern” solution for modular storage.

The Case for HDPE (The Industrial Specialist)

HDPE remains the go-to for Heavy Industrial Chemical Plants or environments where the lockers will be subjected to extreme chemical spills that might degrade other polymers.

As an expert China ABS locker factory, we recommend the ABS modular system for 90% of commercial applications due to its superior balance of strength, price, and appearance.