Don’t Risk Fines: The Top Regulations to Consider When Buying a New Specialty Gas Cylinder Cabinet

Imagine this scenario: An inspector walks into your laboratory or industrial workshop. They stop at your Gas Cylinder Cabinet . They pull out a clipboard. A few weeks later, your company is hit with a massive fine, or worse—operations are shut down due to “unsafe handling of hazardous materials.”

This isn’t a scare tactic; it is a reality for facilities that overlook the critical regulations governing specialty gas storage.

Whether you are managing a university research lab, a semiconductor fabrication plant, or a heavy-duty welding workshop, the storage of compressed gases—especially flammable, toxic, or corrosive ones—is not just about organization. It is about life safety and legal compliance.

In this guide, we will break down the complex world of OSHA and NFPA regulations into simple, actionable advice. We will explore what features your gas cylinder cabinet must have to keep you safe, compliant, and fine-free.

🛑 The Cost of Non-Compliance: It’s More Than Just Money

Before we dive into the specific rules, let’s understand the stakes. Failing to store gas cylinders correctly can lead to:

- Explosions and Fire: Flammable gases like Hydrogen or Propane are unforgiving. A small leak without proper ventilation can lead to catastrophic failure.

- Health Hazards: Toxic gas leaks can incapacitate workers in seconds.

- Regulatory Fines: OSHA violations can cost upwards of $16,131 per violation, with “willful” violations soaring over $161,323.

- Insurance Voids: Many insurance policies have clauses that void coverage if the facility was not adhering to fire codes (NFPA) at the time of an incident.

The solution? Investing in a Certified, Intelligent Gas Cylinder Cabinet that automates safety.

📜 The “Big Two” Regulations About Gas Cylinder Cabinet You Need to Know

When buying a cabinet, you don’t need to memorize every law, but you must be familiar with the two main governing bodies: OSHA and NFPA.

1. OSHA (Occupational Safety and Health Administration)

- The Core Rule: OSHA 1910.101 (Compressed Gases).

- What it means for you: OSHA mandates that cylinders must be stored in a well-ventilated area, protected from external heat sources, and secured to prevent falling.

- The Solution: You need a cabinet made of sturdy material (like cold-rolled steel) with internal securing chains.

2. NFPA (National Fire Protection Association)

- The Core Rule: NFPA 55 (Compressed Gases and Cryogenic Fluids Code).

- What it means for you: This is the “Bible” for fire safety. It dictates that flammable gases must be separated from oxidizing gases. Crucially, it requires continuous mechanical ventilation and leak detection for hazardous gases stored indoors.

- The Solution: A standard locker isn’t enough. You need a cabinet with an integrated Automatic Exhaust System and Combustible Gas Detectors.

✅ The 4 Gas Cylinder Cabinet Must-Have Features for Regulatory Compliance

Now that we know the rules, how do you choose a product that satisfies them? Do not settle for a basic metal box. To ensure you don’t risk fines, look for these four specific engineered features found in high-quality Gas Cylinder Cabinets.

Feature 1: Intelligent Leak Detection & Alarm Systems of Gas Cylinder Cabinet

Regulation addressed: Early warning requirements for hazardous leaks.

You cannot rely on the human nose to detect a leak. By the time you smell gas, it might be too late.

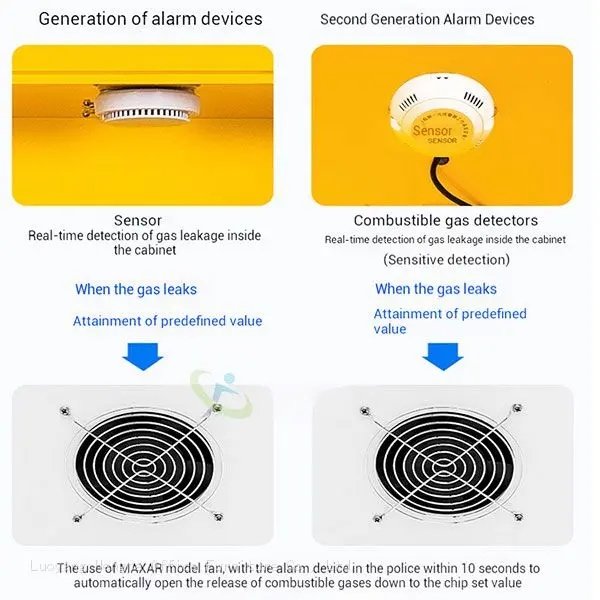

Top-tier cabinets, such as our OSHA-Ready Flammable Gas Cabinet, come equipped with a Second Generation Sensor.

- How it works: The sensor provides real-time detection of gas leakage inside the cabinet.

- The Alert: If the gas concentration reaches a predefined value, the system triggers an audible buzzer (85db) and a red visual flash alarm.

- Why you need it: This immediate notification allows personnel to evacuate or shut off valves before the gas reaches explosive limits.

Feature 2: Automatic Ventilation & Exhaust of Gas Cylinder Cabinet

Regulation addressed: NFPA 55 requirement for continuous ventilation of gas cabinets.

Detecting a leak is step one. Removing the gas is step two.

Our cabinets feature an integrated MAXAR model fan linked to the alarm system.

💡 The Smart Safety Sequence:

When the sensor detects a leak, the fan automatically starts within 5 to 10 seconds. It actively sucks the combustible gas out of the cabinet and pushes it through the exhaust ducting to a safe outdoor area. This rapidly lowers the gas concentration back to a safe level.

Feature 3: Robust Construction & Physical Security of Gas Cylinder Cabinet

Regulation addressed: OSHA requirements for cylinder stability and protection.

Gas cylinders are heavy and pressurized missiles if mishandled. Your cabinet needs to be a fortress.

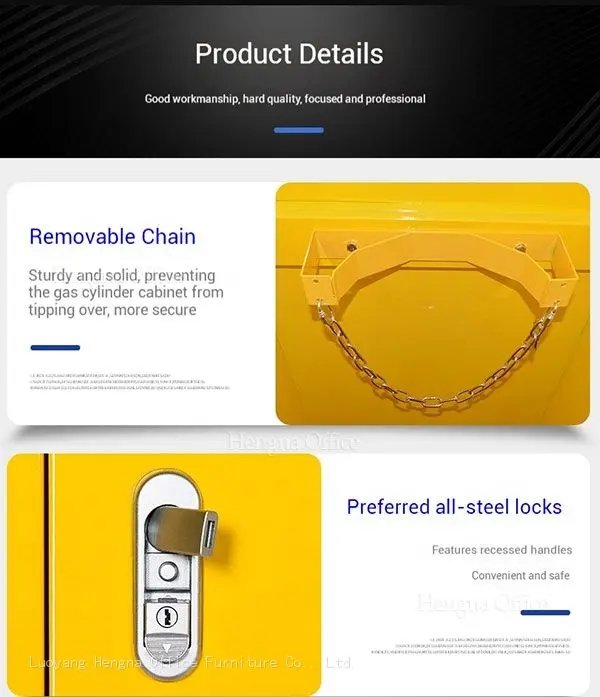

- Material: Look for thickened cold-rolled steel plate construction. This provides fire resistance and impact protection.

- Securing: The cabinet must have internal chains and a removable mounting bracket to strap the cylinders tight, preventing them from tipping over during an earthquake or accidental bump.

- Access Control: To prevent unauthorized tampering (a major compliance risk), ensure the cabinet has a high-strength embedded steel lock.

Feature 4: Ergonomics & Operational Safety of Gas Cylinder Cabinet

Regulation addressed: General Duty Clause (preventing workplace injuries).

Compliance isn’t just about the gas; it’s about the worker handling it. Lifting heavy cylinders is a leading cause of back injury.

Look for a cabinet with an adjustable loading and unloading pedal. This simple ramp allows workers to roll cylinders in smoothly without heavy lifting, reducing injury claims and improving daily efficiency.

📊 Comparison: Standard Locker vs. Intelligent Safety Cabinet

Why pay more for a specialized cabinet? This table highlights the difference between “Storing” and “Securing.”

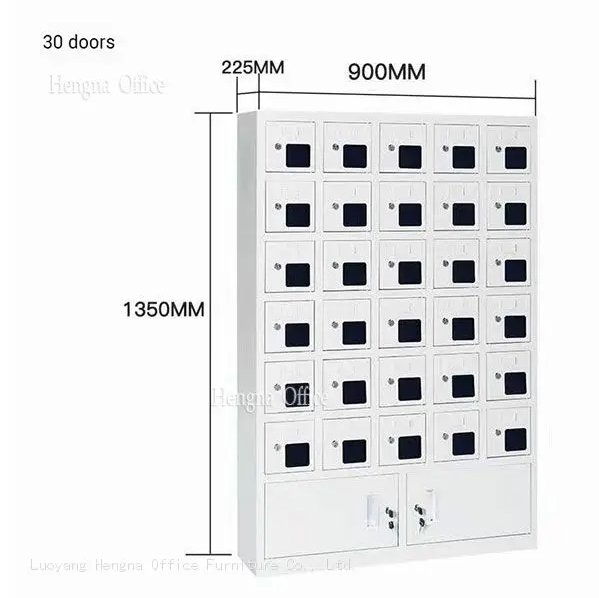

| Feature | Standard Metal Locker | Intelligent Gas Cylinder Cabinet |

| Material | Thin Sheet Metal | Heavy-Duty Cold Rolled Steel |

| Leak Detection | None (Relies on smell) | High-Sensitivity Combustible Gas Sensor |

| Ventilation | Passive (Louvers only) | Active Automatic Exhaust Fan System |

| Response Time | N/A | Fan activates in <10 seconds of leak |

| Cylinder Loading | Manual Lifting (Risk of injury) | Portable Loading Pedal Ramp |

| Compliance | Risk of Fines | OSHA & NFPA Ready |

🛠️ Installation Tips of Gas Cylinder Cabinet for Full Compliance

Buying the cabinet is the first step. Installing it correctly is the second. Here is a quick checklist for your facility manager:

- Exhaust Connection: Utilize the ventilation flange on top of the cabinet to connect it to your facility’s external exhaust system.

- Power Supply: Ensure you have a power source nearby for the alarm and fan system. Our cabinets include a power cord reserve hole for easy, organized wiring.

- Gas Lines: Do not drill random holes in your cabinet. Use the pre-designed gas line pass-through holes to route tubes from the cylinder to your equipment safely.

- Leveling: Use the adjustable feet to ensure the cabinet is perfectly level, ensuring the doors close properly and the sensor works accurately.

🏭 Which Gas Cylinder Cabinet Size Do You Need?

Regulations often require separating incompatible gases (e.g., Oxygen and Acetylene). We offer modular solutions to meet these spacing rules:

- Single Cylinder Cabinet (1900x500x450mm): Perfect for small labs needing to isolate a single toxic or flammable gas.

- Double Cylinder Cabinet (1900x900x450mm): The industry standard for welding stations or dual-gas setups.

- Triple Cylinder Cabinet (1900x1200x450mm): Ideal for high-volume storage needs, maximizing space while maintaining safety.

Note: All sizes are available in Yellow (Warning) or White/Grey (Lab/Medical) colors.

🎯 Conclusion: Safety is an Investment, Not a Cost

When you evaluate the price of a Gas Cylinder Cabinet, do not just look at the hardware cost. Factor in the “cost avoidance”—avoiding OSHA fines, avoiding fire damage, and avoiding business interruption.

By choosing a cabinet with integrated alarms, automatic ventilation, and rugged steel construction, you are not just buying storage; you are buying peace of mind.

Ready to upgrade your facility’s safety standards?

Don’t wait for the inspector to arrive. [Contact Us Today] to discuss your specific gas storage needs and get a quote on our OSHA-ready cabinets. We offer ODM/OEM customization to fit your exact lab or factory layout.