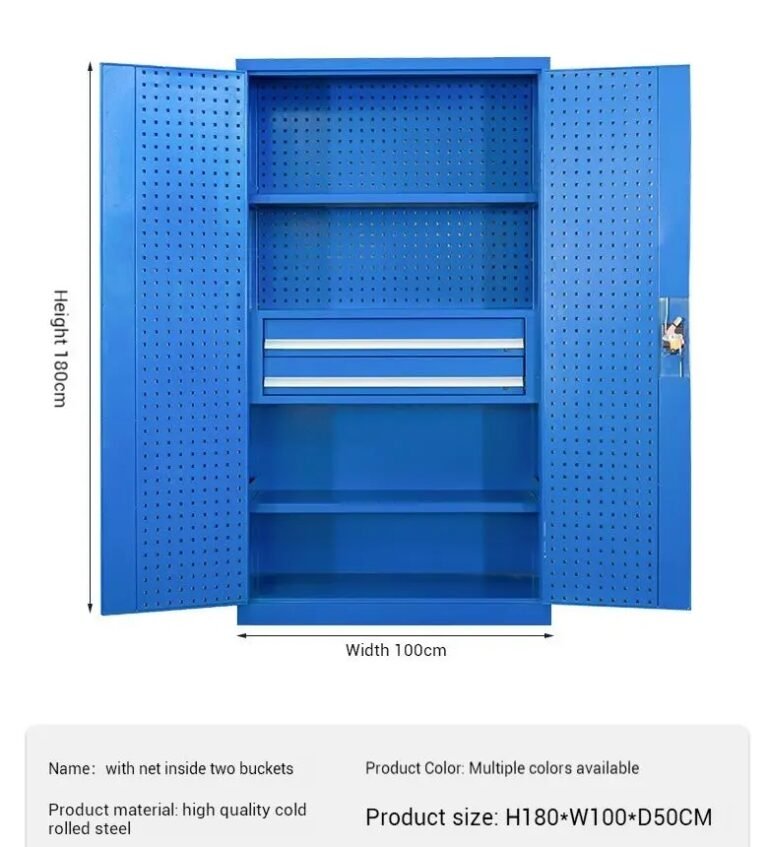

Heavy Duty CNC Tool Storage Cabinet | Steel Rack for BT30/BT40/BT50 Holders

In modern machining workshops and CNC centers, organization is not just about neatness—it’s about efficiency and protecting your investment. Expensive CNC tool holders, milling cutters, and drill bits left on benches are prone to damage and dust.

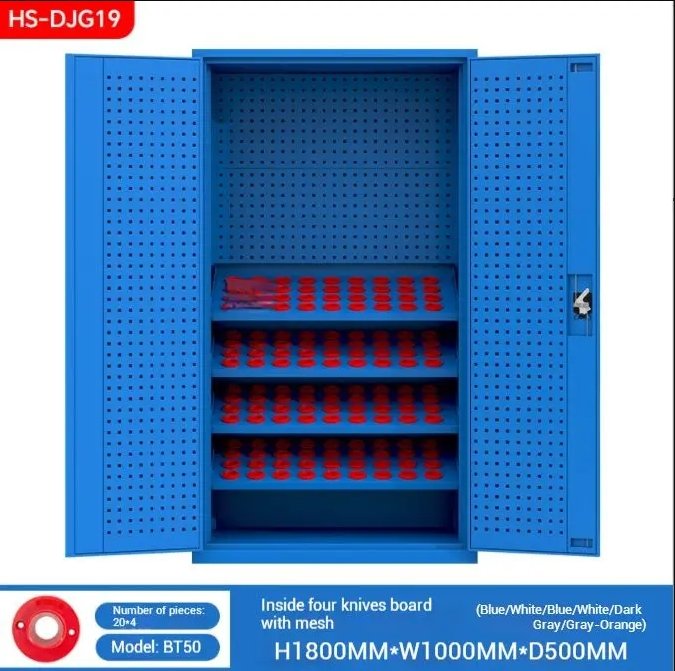

Luoyang Hengna Office Furniture presents the Industrial CNC Tool Storage Cabinet (Model HS-DJG19). Engineered specifically for the manufacturing sector, this heavy-duty steel cabinet combines high-density storage for taper tool holders (BT, CAT, and HSK series) with versatile pegboard doors for hand tools. It is the central station for your machine tooling workflow.

1. Key Features: Designed for Machinists

This cabinet is packed with features that solve specific workshop problems.

Specialized CNC Tool Storage System

The heart of this cabinet is its specialized shelving system.

- ABS Tool Cups: The cabinet comes with durable ABS plastic inserts (red/blue options) designed to snugly fit standard CNC tapers.

- Compatibility: We offer racks compatible with BT30, BT40, BT50, and HSK standards.

- Capacity: The standard unit includes 4 angled knife boards. Each board is reinforced to hold the significant weight of solid carbide tools without bending.

- Protection: By storing tools vertically in individual cups, you prevent cutting edges from chipping against each other.

Integrated Pegboard Doors

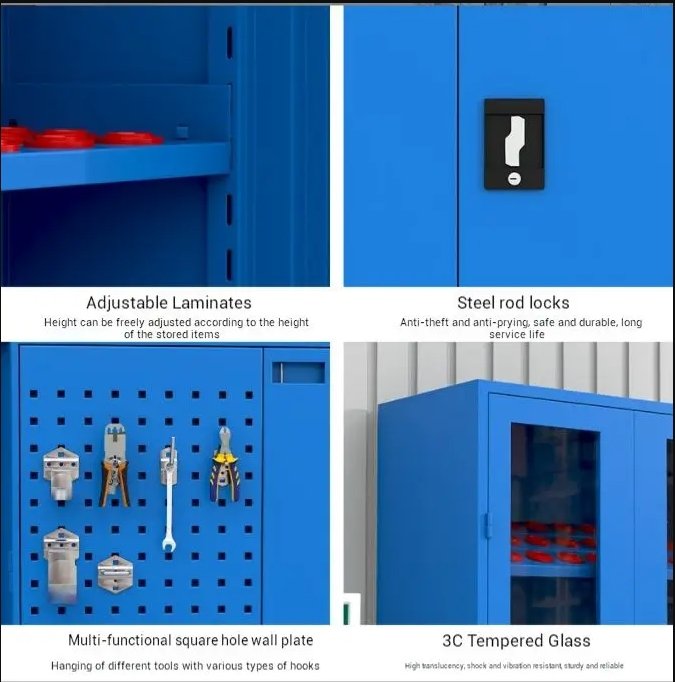

Don’t waste the door space. The interior of both doors features a “multi-functional square hole wall plate.”

- Versatility: Compatible with standard square-hole hooks.

- Usage: Perfect for hanging wrenches, pliers, calipers, and other hand tools needed for tool changes. This keeps everything a machinist needs in one lockable unit.

Secure & Durable Construction

- Steel Rod Locks: Security is paramount for expensive tooling. We use a “steel rod lock” system (often called a 3-point latch). The latch secures the door at the top, bottom, and center, making it anti-theft and anti-prying.

- Heavy-Gauge Steel: Built from premium cold-rolled steel to withstand the rough environment of a factory floor.

- Adjustable Laminates: The shelf height can be “freely adjusted” to accommodate tools of different lengths, from short drill chucks to long boring bars.

2. Heavy Duty CNC Tool Storage Cabinet Technical Specifications

| Parameter | Specification |

| Model | HS-DJG19 / BT50 Series |

| Dimensions | H1800 x W1000 x D500 mm |

| Material | High-Quality Cold Rolled Steel Sheet |

| Steel Thickness | (Heavy Duty for Industrial Use) |

| Tool Holder Type | Fits BT30 / BT40 / BT50 / HSK63 (Customizable) |

| Shelves | 4 x CNC Tool Holder Shelves + 1 x Flat Shelf (Standard) |

| Door Type | Dual Solid Steel Doors with Internal Pegboard (Standard) Option: 3C Tempered Glass Doors available |

| Lock System | 3-Point Steel Rod Latch with Key Lock |

| Finish | Industrial Powder Coating (Blue/Grey) |

| Features | Anti-tilt, Adjustable Feet, Square Hole Pegboard |

3. Why Use a Dedicated CNC Cabinet?

Implementing a Hengna Tool Cabinet in your facility supports 5S / LEAN Manufacturing principles:

- Reduce Setup Time: Machinists stop wasting time searching for the right tool holder.

- Damage Prevention: Protects precision-ground tapers from dust, moisture, and accidental drops.

- Inventory Control: A quick visual check tells you which tools are in use and which are available.

- Space Saving: Vertical storage holds hundreds of tools in a footprint of less than 0.5 square meters.

4. Heavy Duty CNC Tool Storage Cabinet Application Scenarios

This cabinet is an essential asset for:

- CNC Machining Centers: Storing milling chucks and collets next to the VMC/HMC.

- Automotive Manufacturing: Organizing assembly line tools.

- Aerospace Workshops: Secure storage for high-value precision instruments.

- Vocational Schools: Teaching students proper tool management habits.

- MRO Departments: Maintenance, Repair, and Operations storage.

5. Manufacturing Excellence (Factory Direct)

At Luoyang Hengna, we control the quality because we own the machines.

- Laser Cutting: Our laser cutting machines ensure the square holes on the pegboard are perfectly uniform for easy hook insertion.

- Precision Bending: Our CNC Bending Workshop ensures the shelves are rigid and perfectly aligned to handle heavy loads.

- Powder Coating: We use an industrial-grade electrostatic powder coating that resists oil, grease, and scratches common in machine shops.

6. Customization Options (OEM/ODM)

We understand every workshop is different.

- Color: Standard Industrial Blue (RAL 5012) or Grey (RAL 7035). Custom brand colors are available.

- Door Style: Choose between solid steel for maximum security or “3C Tempered Glass” for visibility.

- Internal Layout: Need more flat shelves for heavy jigs? Need fewer tool holder racks? We can configure the interior to your specs.

7. FAQ (Frequently Asked Questions)

Q: How do I know which tool holder size to order? A: Please check your CNC machine spindle type. The most common are BT30, BT40, and BT50. We provide the corresponding red ABS plastic inserts based on your requirement.

Q: What is the load capacity per shelf? A: Our reinforced CNC shelves are designed to hold approximately 80-100kg per level, depending on the steel thickness selected.

Q: Does the cabinet come assembled? A: To save on shipping costs, these units are typically Knocked-Down (Flat Packed). However, the structure is designed for easy assembly with bolts. We provide a detailed video guide.

Q: Can I add wheels? A: Yes, we can install heavy-duty industrial casters (2 swivel + brake, 2 fixed) to make this a mobile tool station.

9. Request a Quote

Streamline your production floor today.

Contact Hengna Office Furniture for:

- Wholesale Price List.

- Container Load Optimization.

- Custom Color/Logo Printing.