Lab Safety 101: Why Your School Laboratory Needs a Flammable Safety Cabinet

In any environment where chemicals are handled—whether it is a high school chemistry class, a university research center, or a busy industrial factory—safety is not just a guideline; it is a lifeline.

One of the most critical, yet often overlooked, pieces of safety equipment is the flammable safety cabinet. You have likely seen them: those bright yellow, robust steel boxes sitting in the corner of the lab. But do you know what they actually do? And more importantly, does your facility legally require one?

In this guide, Luoyang Hengna Office Furniture Co., Ltd. explores the vital role of these cabinets, the risks they prevent, and the wide range of industries—from chemical plants to auto repair shops—that rely on them for daily protection.

The Hidden Danger: Why Ordinary Cabinets Are Not Enough

Imagine a typical scenario in a school laboratory or a factory workshop. You have bottles of ethanol, acetone, gasoline, or cleaning solvents. Where are they stored?

If they are sitting on an open shelf or inside a standard wooden cupboard, you are sitting on a ticking time bomb.

- Fire Acceleration: In the event of a building fire, standard cabinets burn. The heat causes chemical containers to burst, turning a manageable fire into a catastrophic explosion.

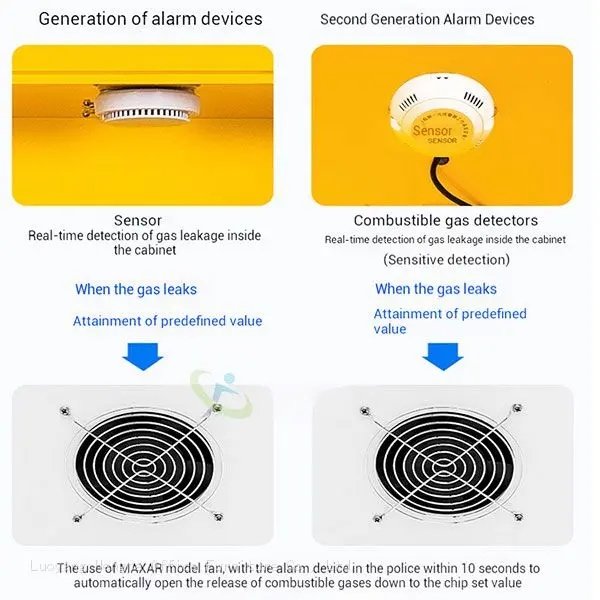

- Vapor Accumulation: Flammable liquids release vapors. Without proper containment and ventilation, these vapors can build up and ignite from a single static spark.

- Spill Hazards: A knocked-over bottle on a wooden shelf soaks in, creating a permanent fire hazard. On a steel shelf, it drips onto the floor, creating a slip hazard and environmental contamination.

A certified flammable safety cabinet eliminates these risks. It is engineered to perform three functions: delay heat, contain spills, and secure access.

Deconstructing the Safety Cabinet: What Makes It “Safe”?

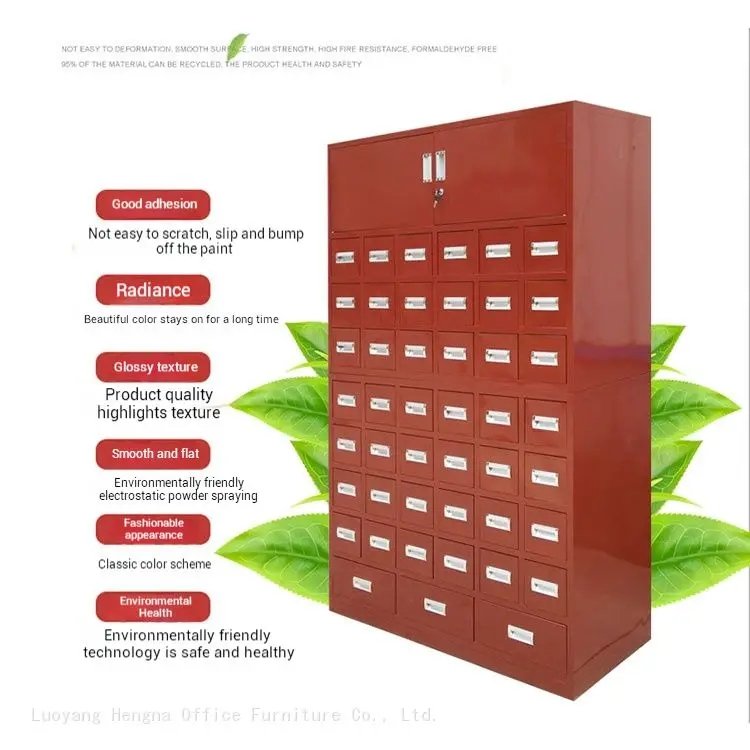

At Hengna, our manufacturing process in Luoyang adheres to strict international standards. Here is what separates a specialized safety cabinet from a metal locker:

- Double-Wall Thermal Barrier: The cabinet is built with two layers of cold-rolled steel. Between these layers is a 38 mm insulating air gap. This air gap acts as a thermal shield, preventing external fire heat from reaching the chemicals inside, buying valuable time for evacuation.

- The Leak-Proof Sump: Look at the bottom of a Hengna cabinet. You will find a 50 mm (2-inch) deep liquid-tight sump. If a container leaks, the chemical stays in this tank, never reaching the floor or drains.

- Flame Arrester Vents: Dual vents allow for ventilation, while built-in flame arresters prevent external fire from “flashing back” into the cabinet.

- Three-Point Latching: The doors are secured at the top, bottom, and center, ensuring a tight seal that contains fire and vapors even under intense heat.

Beyond the Classroom: Who Else Needs Protection?

While our title mentions “School Laboratories,” the need for safe storage extends far beyond education.

Here is a breakdown of the sectors we serve at Hengna Office Furniture and why they need our cabinets:

1. Heavy Industry & Chemical Production

- Chemical Plants & Fine Chemical Lines: Handling volatile raw materials is daily business. Safety cabinets segregate incompatible chemicals (e.g., separating flammables from oxidizers) near the production line.

- Resin, Ink, & Paint Factories: These facilities store large volumes of solvents. Our 60-gallon and 90-gallon vertical cabinets are standard requirements here.

- Pharmaceutical & Bio-Labs: Precision and sterility are key, but so is fire safety when using alcohol-based sterilization agents and solvents.

2. Maintenance & Manufacturing Services

- Auto Repair & Paint Shops: Spray painting vehicles involves thinners, primers, and lacquers—all highly flammable. A yellow safety cabinet is a staple in every professional body shop.

- Welding & Cutting Workshops: Sparks fly constantly in these environments. Storing acetylene or other fuel sources in a fireproof cabinet prevents stray sparks from causing disasters.

- Metalworking (Gold/Silver) Workshops: Often use acids and flammable cleaning agents for refining metals.

3. Specialized Commercial Sectors

- Electronics Factories: The manufacturing of PCBs often requires isopropyl alcohol (IPA) and other solvents for cleaning. These must be stored in anti-static grounded cabinets.

- Logistics & Warehousing Centers: Any warehouse storing third-party hazardous goods needs a designated “Red Zone” or safety cabinet storage area to comply with insurance policies.

- Food Processing Plants: While not “chemical” plants, they use large quantities of food-grade heavy-duty cleaners and high-concentration alcohol for machinery sanitation.

4. Healthcare & Public Safety

- Hospitals & Medical Centers: Pathology labs and operating theaters store tissue fixatives and disinfectants that are flammable.

- Safety Regulatory Departments: Government testing labs themselves use these cabinets to set the standard for safety.

Compliance: The Legal “Why”

Investing in a Hengna safety cabinet is not just about safety; it is about legality.

- OSHA 29 CFR 1910.106: Limits the amount of flammable liquid that can be stored outside of a safety cabinet. Violating this can lead to massive fines.

- NFPA Code 30: Specifies the construction requirements (such as the double-wall steel and 3-point lock) that our cabinets meet.

By installing compliant storage, you reduce your insurance premiums and pass safety inspections with ease.

How to Choose the Right Cabinet?

When ordering from Hengna, consider these three factors:

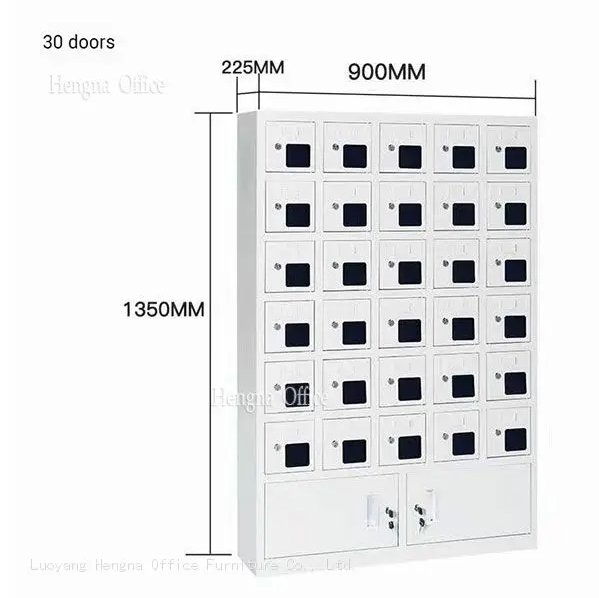

1. Volume (Gallons): Do you need to store a few small bottles or large 55-gallon drums?

- 4-12 Gallons: Perfect for under-counter storage in school labs or hospital stations.

- 30-45 Gallons: The standard size for workshops and auto repair shops.

- 60-90 Gallons: Ideal for industrial chemical plants and warehouses.

2. Door Type:

- Manual Doors: Open a full 180 degrees. Economical and reliable.

- Self-Closing Doors: Automatically close and latch if the temperature reaches 74°C (165°F). Mandatory in some US states and specific high-risk zones.

3. Color Coding:

- Yellow: For Flammables (Alcohol, Gasoline).

- Red: For Combustibles (Diesel, Oil).

- Blue: For Corrosives (Acids—Note: Hengna also offers polyethylene-lined blue cabinets for strong acids).

Whether you are a chemistry teacher protecting thirty students or a plant manager overseeing a hazardous chemical line, the risk of fire is the same. A spill takes seconds to happen, and a fire takes minutes to destroy a facility.

At Luoyang Hengna Office Furniture, we provide factory-direct, certified safety solutions. We don’t just sell cabinets; we sell peace of mind.

Are your chemicals stored safely? Don’t wait for an inspection or an accident. Contact Ivy today for a consultation on the right safety cabinet size for your facility. We offer wholesale pricing and OEM customization for global partners.